A needle head for every need

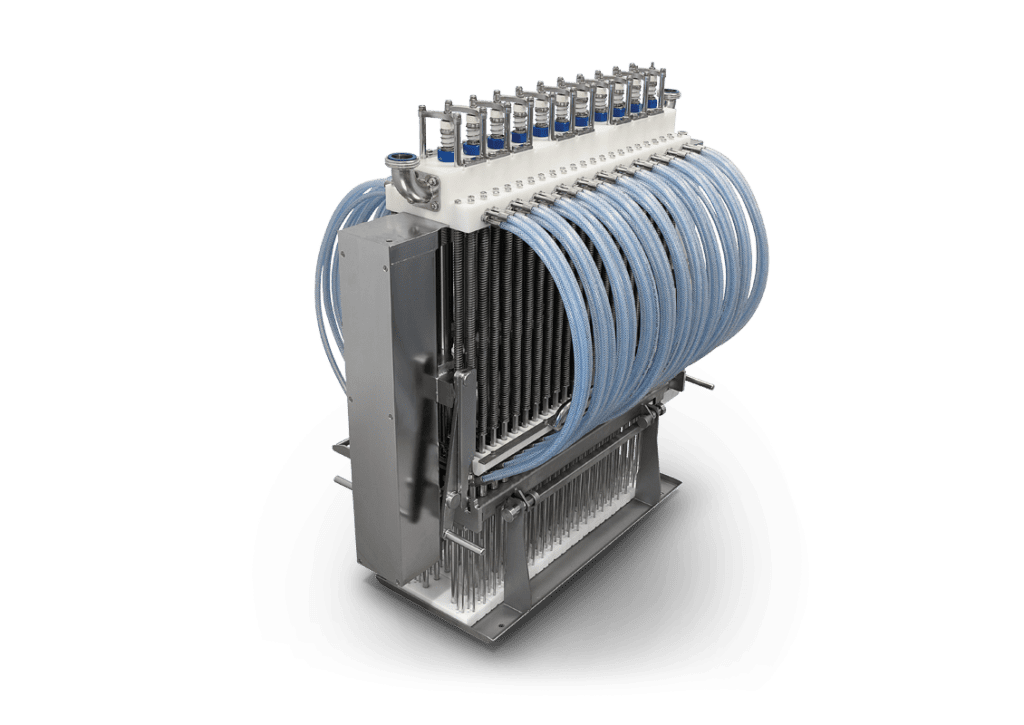

MP14 NEEDLE HEAD

With a stroke height of 0-240 mm, a max product clearance of 200 mm and a design for both bone-in and boneless meat products the MP14 is the most flexible needle head in the M3 range.

Due to the dual pressure air cylinders the stripper feet can apply low pressure to the product on the downstroke and an increased pressure on the upstroke. Because the stripper feet have an exceptional hold on the product the injection is controlled on both the down- and upstroke, making the MP14 extremely precise.

Moreover, the needle head can be setup with differential injection allowing for an optimized production of full

middles or back bacon. This combined with the numerous needle options and the ability to quickly change the full needle cassette makes the MP14 adaptable to all production requirements.

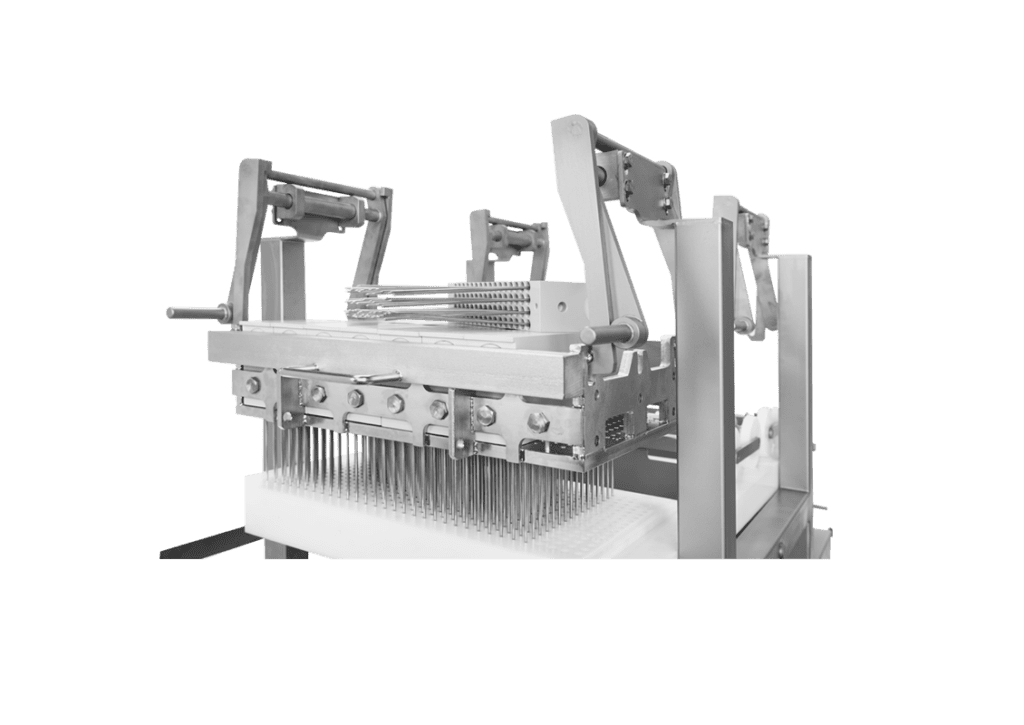

Bip needle head

The BIP injector is ideal for extremely high volumes of bone-in low profile products such as chicken portions, drumsticks, chicken wings etc. With its special bone rejecting system the injector handles low profile bone-in products in unprecedented very high volumes.

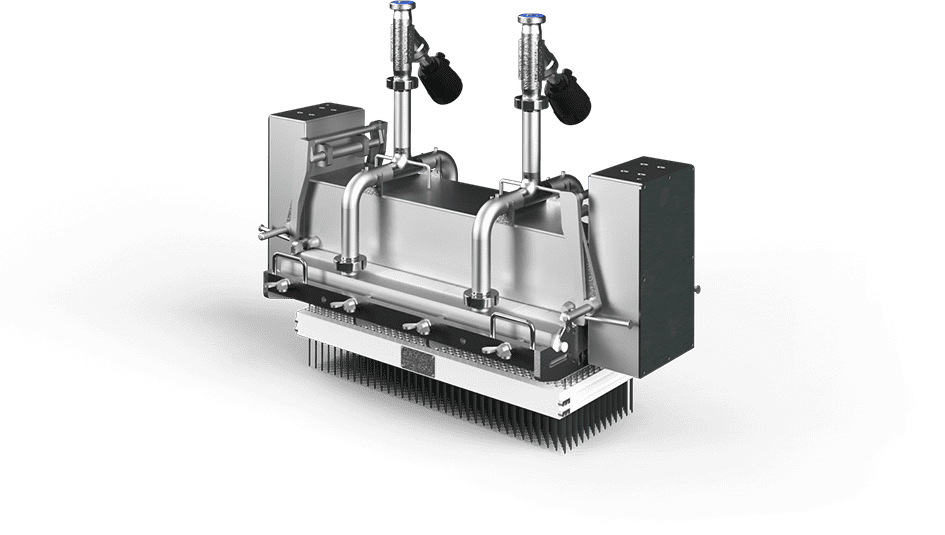

Blp NeedLE Head

The BLP needle head developed for boneless meat products is the perfect choice for high volume production, as it enables you to achieve impressive output rates ranging from 1-15 ton/hr depending on product and injection level. Due to the large amount of needles and the extremely close needle pattern the BLP needle head is especially suited for delicate products.

Technical specifications

MP14 NEEDLE HEAD

- A self-cleaning seat valve design

- Designed as a pump-to-product system for improved hygiene

- A wash table for all loose parts during cleaning

- Designed with a self-cleaning brine distribution channel for improved hygiene

Advancement: 30-45-60 mm

Stroke height: 0–240 mm

Stripping heights H1: 0-200 mm

Available needle types:

Single – Double – Quadro

Injection area W1 x L1

FGM 48 420 x (60) mm

FGM 64 550 x (60) mm

FGM 88 750 x (60) mm

FGM 112 950 x (60) mm

Number of needles

FGM 48 48 pcs

FGM 64 64 pcs

FGM 88 88 pcs

FGM 112 112 pcs

Compatibility

FGM 48 / FGM 64 / FGM 88 / FGM 112

- Reduction in wear parts on needle head

- Uniform needle pattern

- Product activated brine valves

BIP NEEDLE HEADS

With the BIP quick release system you can dismantle the full needle cassette in a matter of seconds.

Inspection, cleaning and disinfection has never been easier!

This also allows for an instant exchange with a clean needle cassette.

In addition, the needle head features:

- Designed as a pump-to-product system for improved sanitation

- Improved cleaning facilities for needles and lower needle head section

Tank units

Advancement: 87-130-260 mm

Stripping heights H1: 25-35-45-55-65-75-85-95 mm

Available needle types: Single

Injection area W1 x L1

FGM 48 360 x 260 mm

FGM 64 540 x 260 mm

FGM 88 720 x 260 mm

Number of needles

FGM 48 408 pcs

FGM 64 612 pcs

FGM 88 816 pcs

- The uniform and dense needle pattern

- Few wear parts

BLP DS & BLP 120 NEEDLE HEADS

With the BLP quick release system you can dismantle the full

needle cassette in a matter of seconds. Inspection, cleaning and

disinfection has never been easier! This also allows for an instant

exchange with a clean needle cassette.

In addition, the needle head features:

- Designed as a pump-to-product system for improved hygiene

- A wash table for all loose parts during cleaning

- Improved cleaning functionality for needles and lower needle head section

Advancement: 87-130-260 mm

Stripping heights H1: 55-75-95 mm

Available needle types: Double – Quadro

Injection area W1 x L1

FGM 48: 400 x 260 mm

FGM 64: 540 x 260 mm

FGM 88: 720 x 260 mm

FGM 112: 900 x 260 mm

Number of needles

FGM 48: 260 pcs

FGM 64: 351 pcs

FGM 88: 468 pcs

FGM 112: 611 pcs

Compatibility

FGM 48 / FGM 64 / FGM 88 / FGM 112

- Uniform and close needle pattern

- Minimal wear parts

THE NUMBERS TO PROVE IT

Over the past 45+ years Fomaco has gained global recognition. Our passion, creativity and hard work has got us where we are today and it is the same core values, which will see us into the future.