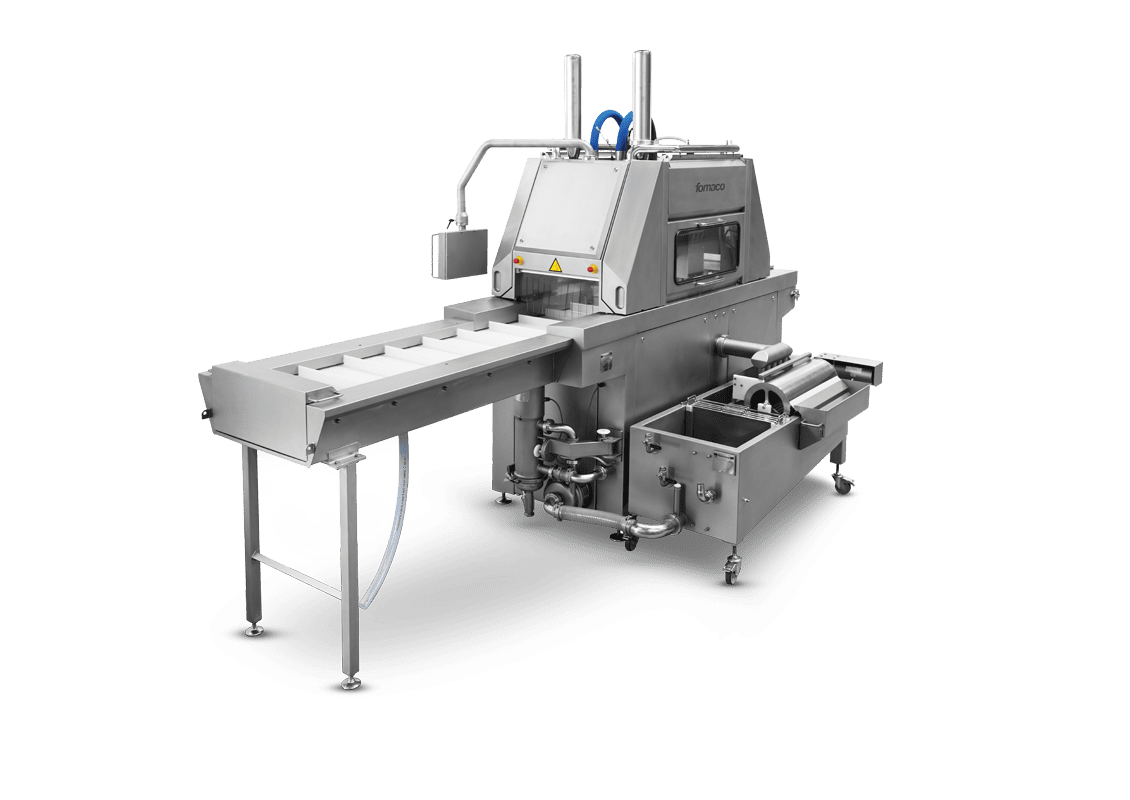

Bip portion control

RELIABLE - EVEN IN AGGRESSIVE ENVIRONMENTS

The M3 is a series of thoroughly tested, high quality production machines designed to operate in highly demanding and aggressive production environments. The ‘box-in-box’ construction seals and protects critical electrical components and controls from water ingress, humidity and atmospheric salt.

OPTIMIZED FLOW FROM PUMP TO PRODUCT

At Fomaco we constantly improve and enhance the performance of our machines. Our use of state-of-the-art pump systems has eliminated dead zones and low flow areas, ensuring a constant pressure and a precise flow rate. The result is a uniform brine distribution - regardless of product type, size and number of needles.

INTELLIGENT SOFTWARE FOR IMPROVED PRODUCTION MANAGEMENT

Remote Device Manager (RDM) allows for troubleshooting and updating of the machine directly from the Fomaco facility in Denmark. This both saves valuable production time and minimizes potential downtime. In addition to providing an unlimited number of preprogrammed production profiles, many routines are fully automated:

- Automatic lubrication

- Automatic monitoring of brine temperature

- Automatic control of min. pump pressure

- Automatic troubleshooting

- Automatic cleaning program

Everything is controlled from the both user friendly and highly intuitive touch screen mounted on a swing arm for convenient operation at all angles.

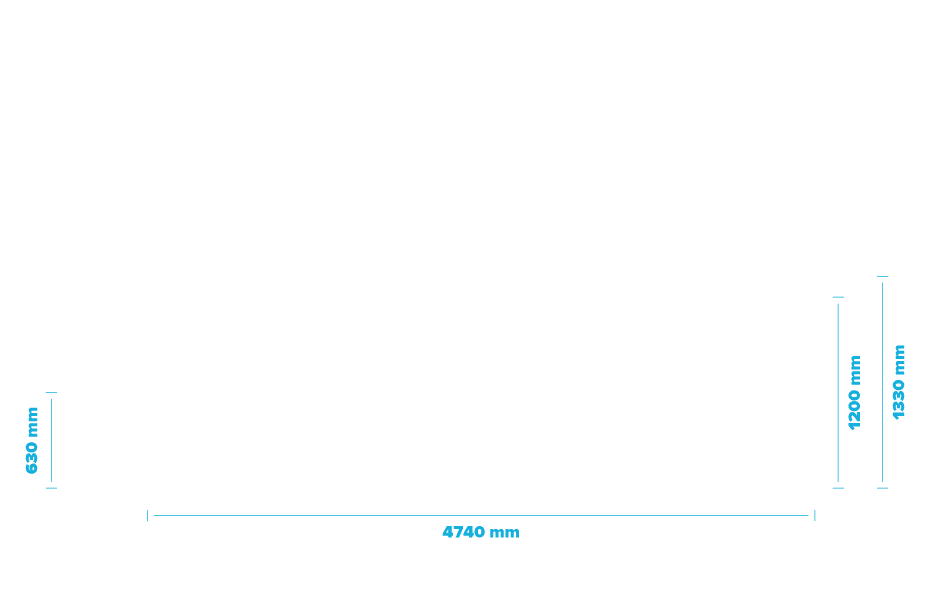

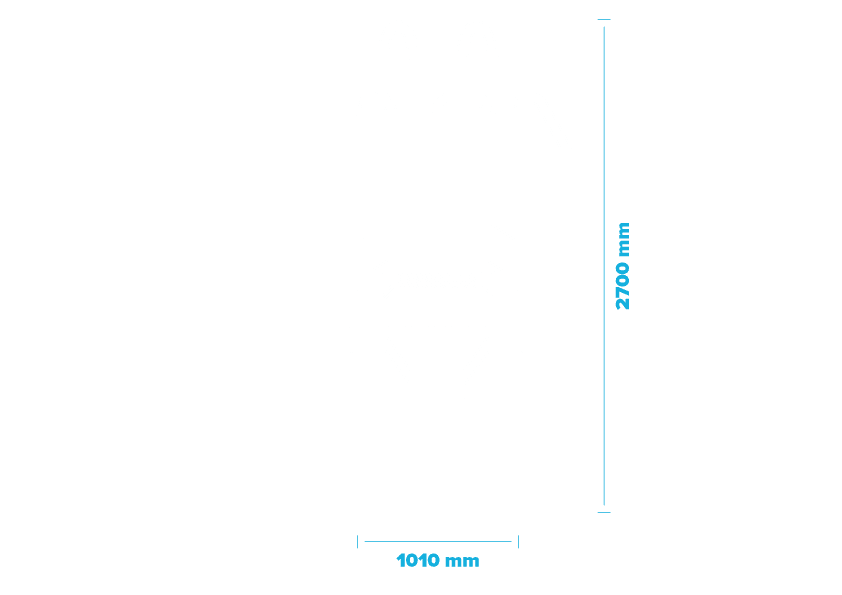

Technical specifications

BIP PORTION CONTROL

With the BIP quick release system you can dismantle the full needle cassette in a matter of seconds. Inspection, cleaning and disinfection has never been easier! This also allows for an instant exchange with a clean needle cassette.

In addition, the needle head features:

- Designed as a pump-to-product system for improved hygiene

- A wash table for all loose parts during cleaning

- Improved cleaning functionality for needles and lower needle head section

Advancement: 255 mm

Stripping heights H1: 70 mm

Available needle types:

Single

Injection area W1 x L1

FGM 64 480 x 245 mm

Tenderizer head ø4-7 knifes

FGM 64 512pcs

Compatibility

FGM 64

- Uniform and dense needle pattern

- Possible Trafo installation

- Possible SCADA integration

- Large windows in the upper doors allow for inspection during operation

| FGM 64 BIP PORTION CONTROL | ||||

|---|---|---|---|---|

| Needle head | Up to 45 strokes per minute | |||

| Transport system | Conveyor belt – plastic (PEHD, Intralox) – Flight height 51 mm – Distance between flights 255 mm | |||

| Transport system (width) | 480 mm | |||

| Weight | 1275 kg |

THE NUMBERS TO PROVE IT

Over the past 45+ years Fomaco has gained global recognition. Our passion, creativity and hard work has got us where we are today and it is the same core values, which will see us into the future.